Case studies

A concrete case, close to your reality in the field, is better than a long speech…

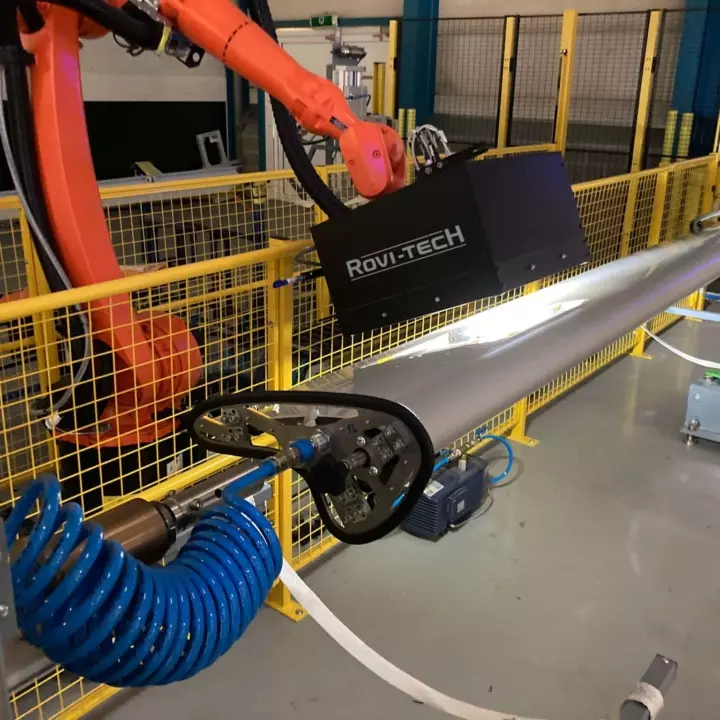

Inspection of aircraft wing leading edges

For SLAT inspection, we have developed a robotized cell capable of analyzing the entire SLAT surface after painting. The main defects detected include: bubbles, dust, scratches, lack of paint, stains, etc. The inspection head, equipped with cameras and lighting, moves automatically to inspect the surface in 200 x 200 mm zones. Defects as small as 1 mm dust in the paint are detected with great reliability. Complete inspection in less than 30 minutes, with 1,000 images acquired and analyzed