We’re interested in your industrial challenge!

Do you need to set up an automated quality control system, automate a process or build or modernize a production machine? Our team and design office Industrie & Développement (ID) are ready to work with you to help you produce at maximum efficiency and minimum cost.

Products

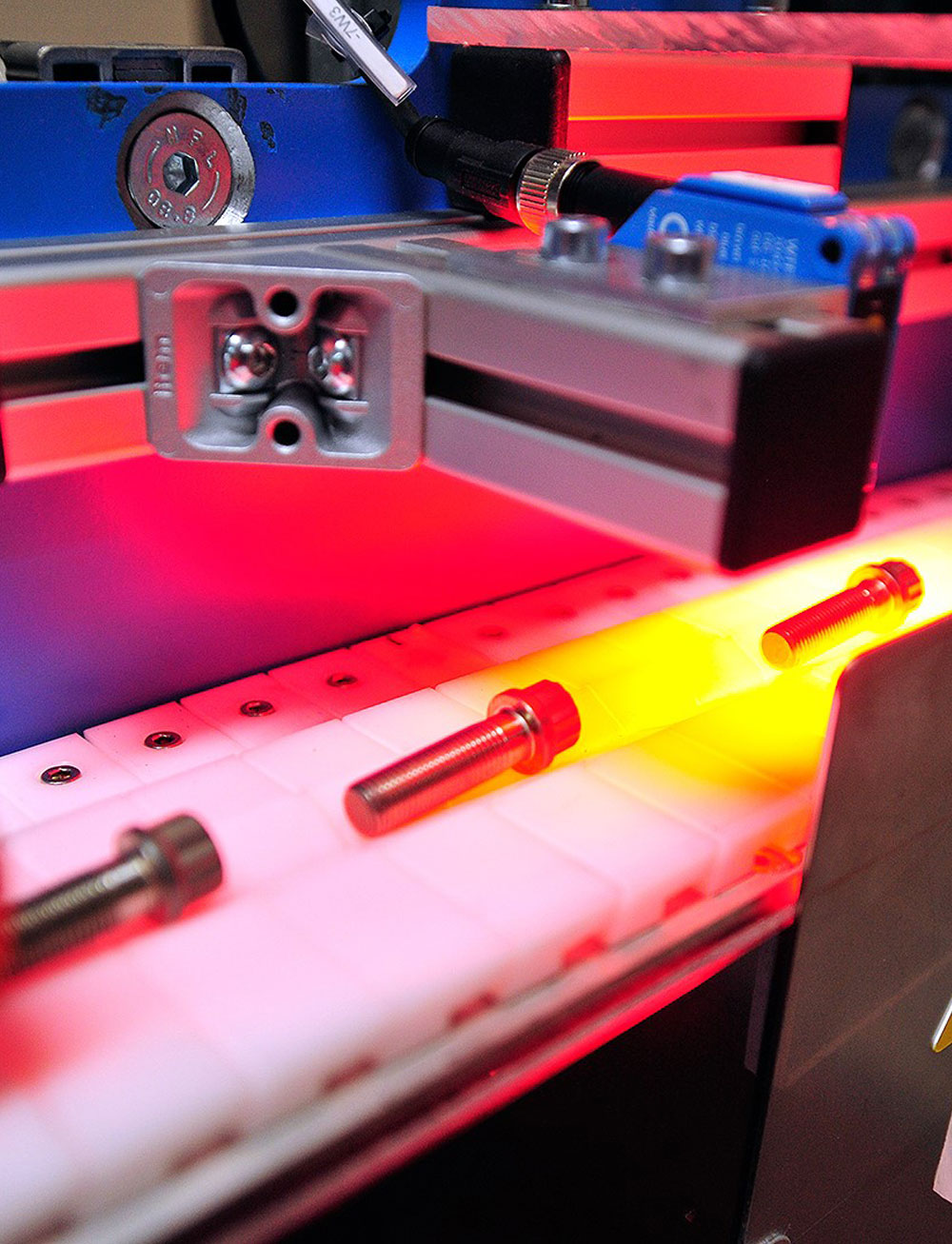

Non-destructive testing (NDT) machines

NDT or CND in French (Contrôle non destructif), three essential initials to produce perfect quality. Desimone is the essential specialist if you want to automate these controls.

Products

Gunning machines

Over 20 years of expertise in this particular gunning sector.

Our range of spraying machines enables refractory concrete to be optimally and safely dispersed into ladles in the steel industry. In addition to shotcreting, other variants of our range can be used for other applications, such as oxygen blowing in the glass industry.

Products

Product handlers

A skilful blend of 2 cutting-edge technologies – robotics and machine vision – enables us to offer you a range of intelligent, innovative robotic cells for a wide variety of sectors.

Products

Special machines

Customization is at the heart of our business. Tell us about your specific needs, and we’ll manufacture the machine(s) that best meet them. We’re active in a wide range of industries, including aerospace, food, glass, steel and aeronautics, and we’re happy to share our experience with you.

Products

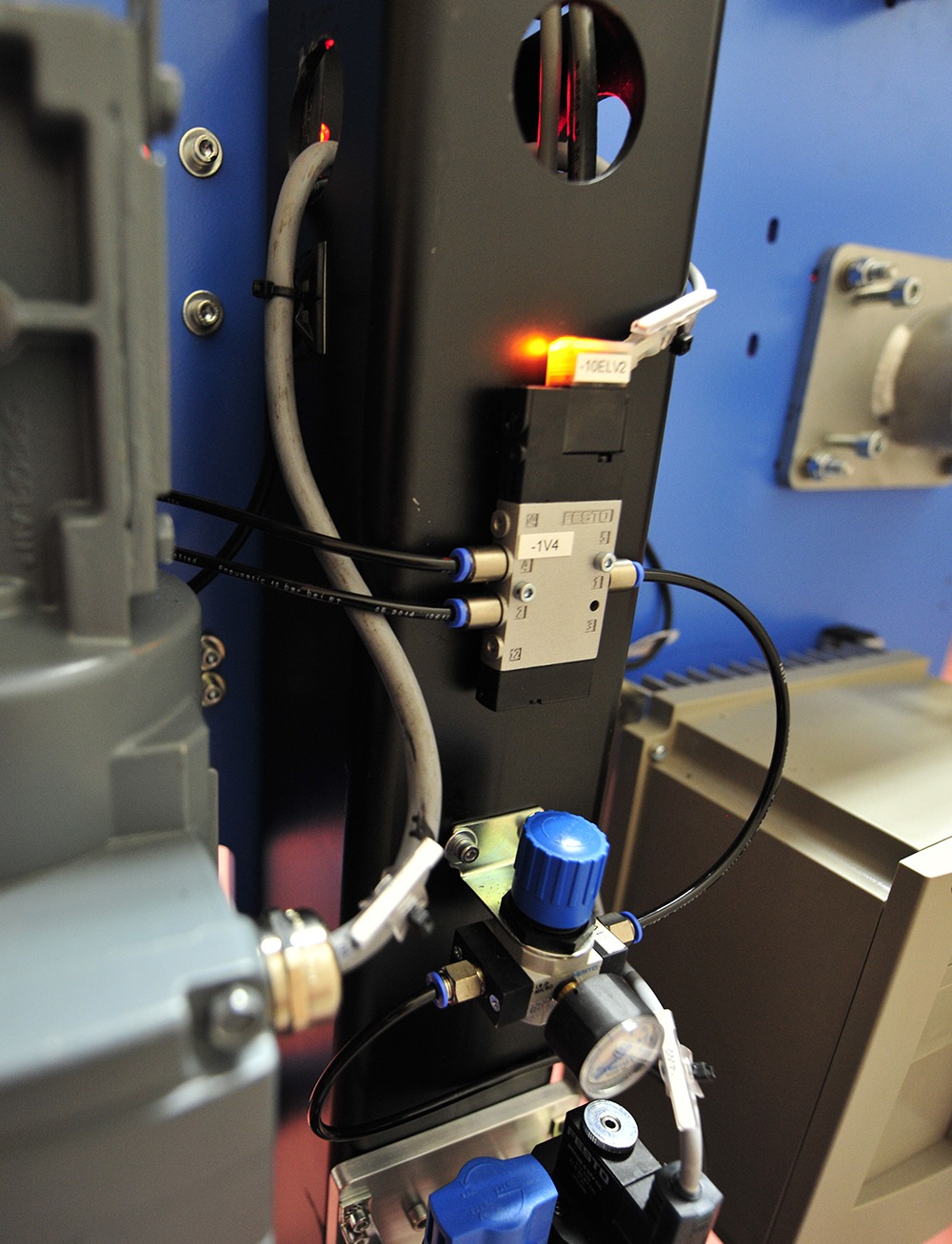

Pneumatic equipment

Desimone is also an industrial equipment store. From simple o-ring seals to the most complex cylinders, we have several thousand items in stock, for emergency repairs or long-term needs. Specialized in pneumatics and automation, and official distributor for FESTO, we also represent other leading brands such as Camozzi, Legris, Transair, Parker Hannifin,…

Our specialist advisers are at your disposal in Farciennes, Monday to Friday, 7.30 a.m. to 4.00 p.m. (closed 12.00 to 12.30 p.m.). To come and see us here.

Independent integrator

What we do

We believe that the future of industry lies in automating industrial processes while ensuring perfect quality control.

We help our customers implement :

ZERO DEFECT AUTOMATION

Automation

We help our customers to :

– Automate their production lines

– Improve manufacturing efficiency

– Reduce operating costs

Zero defects

While contributing to :

– Achieving the highest possible manufacturing quality

– Improve customer satisfaction

Contact

Rue Fontenelle, 18 B-6240 Farciennes Belgium

Monday-Friday: 8am – 5pm

Write to us

We’d love to help!