Product manipulators Products

Discover hereunder some of our standard applications available for the hollow glass industry, but also for injection mould manipulators,…

Cold End hollow glass

You are a producer active in the glass industry for cosmetic products (perfume bottles or jars) or tableware (glass, bottles). It is for sure we can help you to automate your different processes.

PACKBOT

Aimed for cold-end production, these robotic cells automatically pack your products (bottle, jars, glasses) into plastic or carton trays (with or without dividers).

This packing operation is made possible by the usage of a high performance vision system that detects the products coming on a conveyer, one after the other. The vision system gives then instructions to robots that take them and perfectly insert them in the trays.

Our cells accept all kind of glasses colors (transparent, self-colored,..) and shapes.

The number of robots we install depends on the demanded speed of the machine. Each robot can at least pack 50 products/minute.

En fonction de vos besoins et de la spécification de vos produits, notre cellule standard peut-être « customisée ».

Hollow glass decoration

You are a producer active in the glass industry for cosmetic products (perfume bottles or jars) or tableware (glass, bottles). It is for sure we can help you to automate your different processes.

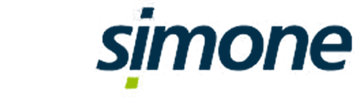

UNPACKBOT

This specific machine fits for decoration activities like screen printing, pad printing, hot stamping, etc. The machine automatically feeds most of the decoration machines of the market (Kamman, Fermac, Isimat, LocaVal, Dubuit,…).

The cell is located close to the entry conveyer of the decoration machine. The products (jars, pots, bottles,…) come in trays (plastic or carton) and the robot first unpacks them, and then aligns them on the conveyer with the right spacing between 2 items.

This unpacking operation is made possible thanks to a highly precise vision system that perfectly detects the position of the products, whatever the kind of glass to manipulate (transparent, colored, glossy or mat…). Even plastic pots or bottles are accepted. The right guidance instructions are then sent to the robots that do the job.

This cell can reach a speed of 70 products/minute.

If you have special needs, contact us and we will together analyze how to customize this robotic cell to perfectly fulfil your needs.

PACKBOT

Aimed for decoration activities, our PACKBOT robotic cells automate the packing process of your decorated hollow glass products, like botlles, jars, pots or drink glasses). They can be either packed in thermoformed plastic trays of carton trays.

These machines are placed right at the output of any standard decoration machine (Kamman, Fermac, Isimat, LocaVal,…). The products are located thanks to a vision system that guides the robots to pick & place them perfectly.

These machines can work with any kind of glass, whatever shape or color (multi color, transparent, glossy, mat,…)

We fix the number of robots that are needed depending on your production speed. One robot alone can already reach a speed of 50 products/min.

We remain fully available to study your specific needs and adapt our standard PACKBOT cell to your specific needs.

Painting machine loading

The aim of these cells is to automatically load your glass products (perfume bottles, jars) before they enter a lacking process.

A first robot takes care of the unpacking of the product, which is originally placed into a tray (carton or thermoformed plastic), and place it in a reference position. The use of vision technology is here crucial to allow the system to unpack any kind of product, whatever its shape or color.

In a second stage, a second robot will insert the product upside down on the tooling axis of your painting machine. We also fit the machine with a quality control of the tooling (axis) of the painting machine, in order to avoid placing a bottle on a defective tool.

Our basic machine is fitted with 2 robots (1 to unload and one to place the product). This combination allows a loading rate of 50 products/minute. If your required speed is higher, we will simply duplicate the number of robots needed, still under the control of one central HMI.

We remain available to further study possible specific needs and adapt our standard machine to your specific needs.

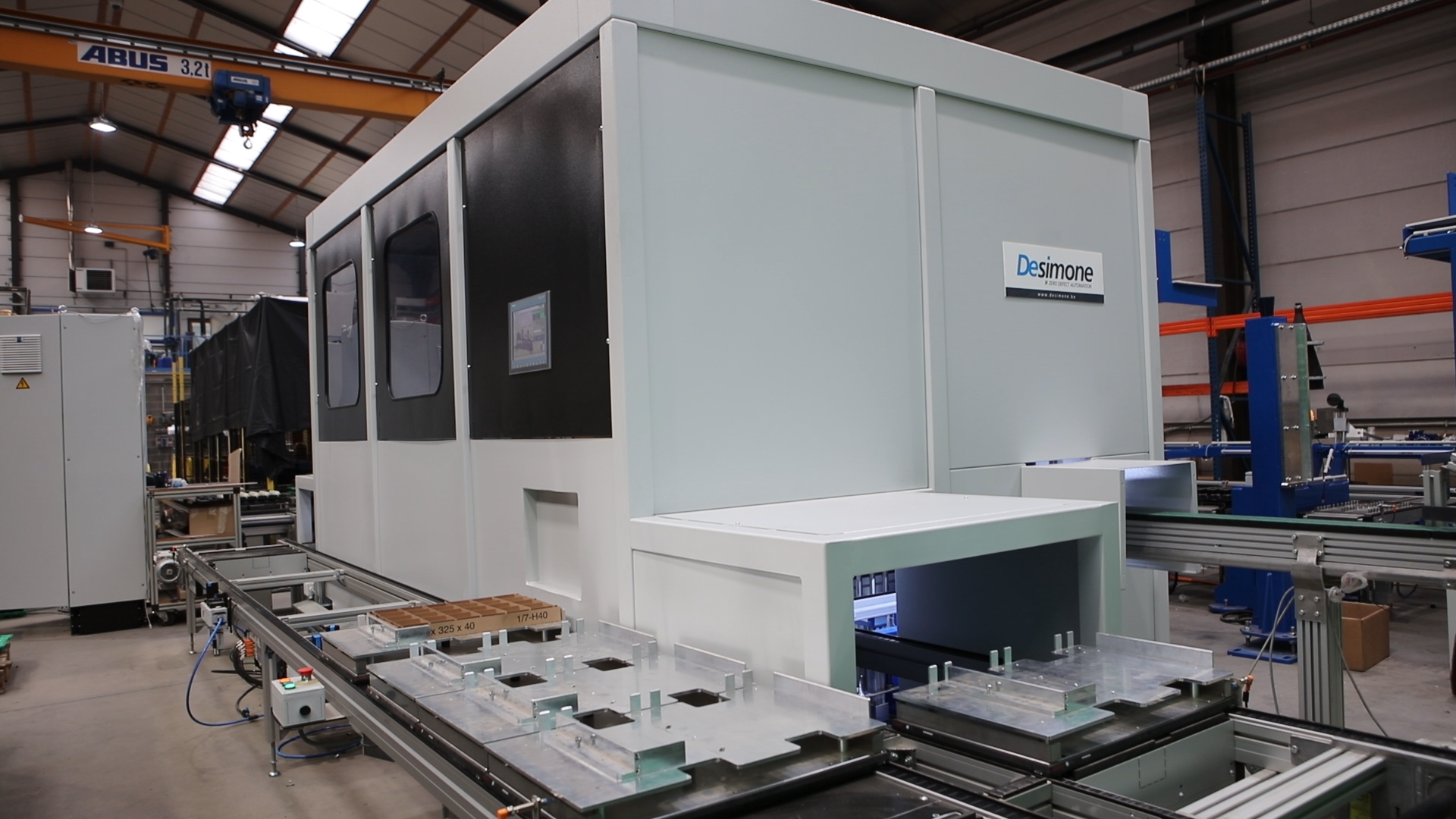

Other

Besides our standard range of machines aiming at manipulating hollow glass containers, there’s much more to discover at Desimone. Our various automated manipulators can handle many different products : from glass bottle to injection moulds weighting several tons !

The combination of robotics and industrial vision technologies allow to automate numerous of manipulation process : please contact us with your inquiry.